Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Loading

Nullam dignissim, ante scelerisque the is euismod fermentum odio sem semper the is erat, a feugiat leo urna eget eros. Duis Aenean a imperdiet risus.

Generally refers to the bearing used in cylinder-related components (such as pistons, crankshafts, etc.), mainly playing the role of supporting and reducing friction, and can adapt to the reciprocating or rotating motion environment in the cylinder. It needs to withstand a certain temperature and pressure, and its structure is designed according to the stress situation. It is commonly used in cylinder components of internal combustion engines, compressors, etc., to ensure smooth movement and extend the service life of components.

Linear bearings are mechanical accessories used in linear motion systems. Their main function is to support and guide moving parts to move smoothly along a linear trajectory and reduce friction. Its structure usually includes a jacket, rolling elements (such as steel balls) and a cage. It relies on the rolling of rolling elements to achieve low-friction motion. It is suitable for scenes with high precision requirements and frequent motion, such as automation equipment, precision instruments, machine tools, etc. Compared with sliding bearings, linear bearings have the characteristics of low friction coefficient, sensitive movement and long life.

Roller bearings are special bearings with rolling elements, which are mainly used to bear radial and axial combined loads and guide rolling parts to move along tracks or curved surfaces. Its structure usually consists of an outer ring (roller), rolling elements, inner ring and cage. The outer ring is mostly an arc surface or a plane, which can be used with guide rails to achieve smooth rolling. It is widely used in conveying equipment, engineering machinery, automated production lines and other scenarios, with the characteristics of strong load-bearing capacity, wear resistance, and adaptability to a variety of motion trajectories.

A rolling bearing that can bear combined radial and axial loads. Its rolling elements are conical, and the raceways of the inner and outer rings are conical, with the conical surfaces converging at the same point on the bearing axis. This structure enables it to bear large radial forces and one-way axial forces at the same time, making it suitable for scenarios requiring combined load bearing, such as automobile wheel hubs, machine tool spindles, and engineering machinery. It has the characteristics of strong load-bearing capacity and good rigidity, but the clearance needs to be adjusted during installation to ensure normal operation.

A bearing that relies on fluid (liquid or gas) as a lubricating medium. It separates the two friction surfaces through a fluid film to achieve non-contact operation. It uses the pressure or viscous force of the fluid to support the load, with an extremely low friction coefficient, stable operation, and low noise. It is suitable for high-speed, high-precision equipment (such as precision machine tools, steam turbines, etc.). However, it has high requirements for fluid cleanliness and system tightness.

A bearing with a compact structure and small axial size, usually adopting a thin design, which can bear axial or radial loads in a limited space. It has a simple structure and is easy to install. It is suitable for equipment with strict space requirements, such as precision instruments, small motors, and office equipment, and has the characteristics of space-saving and stable operation.

A bearing that relies on fluid (liquid or gas) as a lubricating medium. It separates the two friction surfaces through a fluid film to achieve non-contact operation. It uses the pressure or viscous force of the fluid to support the load, with an extremely low friction coefficient, stable operation, and low noise. It is suitable for high-speed, high-precision equipment (such as precision machine tools, steam turbines, etc.). However, it has high requirements for fluid cleanliness and system tightness.

Roller bearings are special bearings with rolling elements, which are mainly used to bear radial and axial combined loads and guide rolling parts to move along tracks or curved surfaces. Its structure usually consists of an outer ring (roller), rolling elements, inner ring and cage. The outer ring is mostly an arc surface or a plane, which can be used with guide rails to achieve smooth rolling. It is widely used in conveying equipment, engineering machinery, automated production lines and other scenarios, with the characteristics of strong load-bearing capacity, wear resistance, and adaptability to a variety of motion trajectories.

A bearing that suspends the rotor by magnetic force (attraction or repulsion) to achieve non-contact operation. It requires no mechanical contact, so there is no friction, no wear, and extremely low noise. It is suitable for high-speed, high-cleanliness, or special environment (such as vacuum, high temperature) equipment, such as turbomolecular pumps and centrifuges. However, it needs a supporting control system to maintain stable suspension, and its structure is relatively complex.

A type of rolling bearing whose rolling elements are slender cylindrical needles (length much larger than diameter), which can bear large radial loads in a small space. It has a compact structure and small radial size, and is suitable for scenarios with limited installation space, such as automobile gearboxes and motorcycle engines. It has the characteristics of strong load-bearing capacity and space-saving, but its rotation speed is relatively limited.

Track bearings are special bearings used in track systems (such as railways, crane tracks, etc.), mainly supporting moving parts on the track (such as wheels, rotation), bearing bearings and fastening bolts.

Its characteristics are wear resistance, strong load-bearing capacity, and can adapt to the continuous impact and heavy load environment of the track, ensuring the smooth movement of moving parts along the track, and widely evaluated in the fields of rail transportation, port machinery, etc.

A bearing with a compact structure and small axial size, usually adopting a thin design, which can bear axial or radial loads in a limited space. It has a simple structure and is easy to install. It is suitable for equipment with strict space requirements, such as precision instruments, small motors, and office equipment, and has the characteristics of space-saving and stable operation.

Bearings run precisely, tires are safe and wear-resistant, we are your reliable choice for auto parts, accompanying you on your journey and ensuring a smooth journey

Years Experience

Vehicle Suitable Accessories

Vehicle Brands

Vehicle Suitable Accessories

Linear bearings

Linear bearings

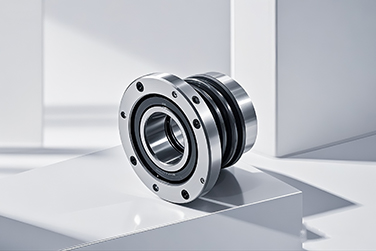

ball bearing

ball bearing

tapered bearings

tapered bearings

fluid bearings

fluid bearings